A combi or system boiler delivers its heat in a closed system that is pressurised, meaning the water in your radiators is filed from the mains and isolated once full rather than the more traditional approach of feeding the system from a storage tank in the loft. If your system is not sufficiently pressurised, the boiler will protect itself from the low water pressure and it will not fire up. The pressure required in this type of system is commonly around 1 bar and the pressure gauge on the front of the boiler will tell you that it is sufficient. If it’s below the required pressure for your boiler it will display this as a fault requiring a ‘top up’ to reset.

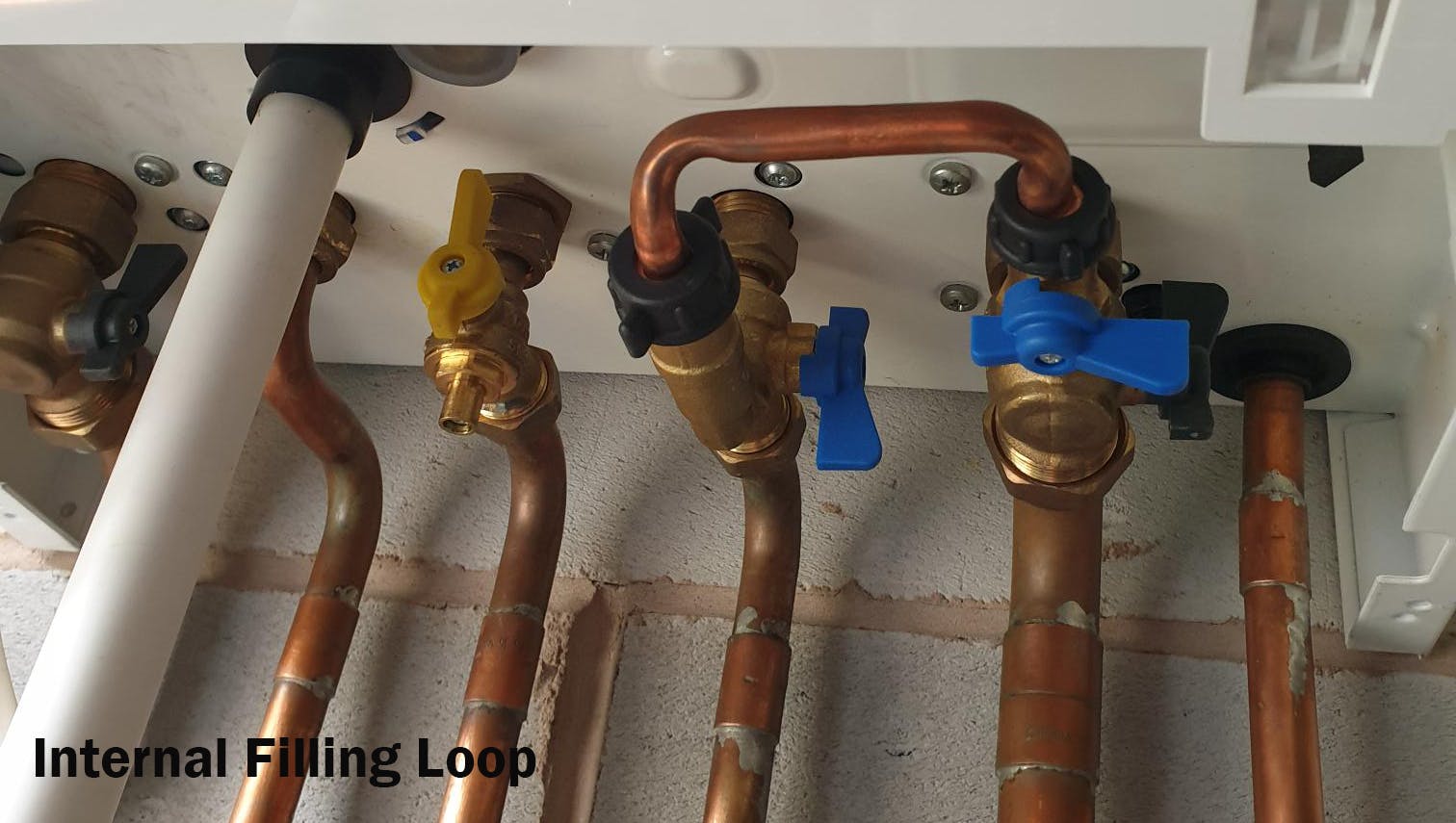

The short-term solution for low boiler pressure is to just top it up, which you can do yourself. There are two types of filling loop; ‘internal’ which is integrated into the boiler itself - and the manufacturer’s instructions will explain the different ways to use them - or an ‘external’ filling loop which is normally a sliver braded hose on the incoming water pipe. On this type there is a valve with a small handle at either end which can be turned (across the pipe is closed, in line with the pipe is open). By carefully opening these quarter turn valves, you will top the system up with water. Monitor the pressure on the pressure gauge or LCD and when it’s around 1 bar, close the valves again to isolate the system from the mains.

This will allow your boiler to fire up again. HOWEVER, this is a short-term solution that temporarily treats the symptom and not the cause of the low pressure. Not only could it see you having to do this frequently to keep the boiler going, whatever is causing the low pressure will not get better on its own. You therefore need to find out what is causing the low pressure and fix it.

There are two main causes of low pressure: a leak on the system pipework and an issue with the expansion vessel.

In a sealed system, a small leak anywhere on the pipework will cause the pressure to drop. This tends to be the most common cause of low pressure and will usually come from a radiator valve or failed joint. To see if this is the case, wipe your hand under radiator valves and visible joints to feel for water.

This may be something you can tighten up or replace yourself, if you know what you’re doing. Otherwise, you’ll need to call in an engineer (who would also be able to test the whole system to make sure that it had resolved the issue).

The expansion vessel is inside the boiler and is charged with air which helps to manage the pressure. Over time, the expansion vessel can lose its charge, and this will cause the pressure to fall. To check whether this is the case, check the pressure relief valve (PRV) blow off for any signs of weeping. This is the small copper pipe that usually terminates on the outside wall that the boiler is mounted on. Another indicator is if you’re most frequently having to top the boiler up when it’s cold outside.

Re-charging the expansion vessel is something that a heating engineer will need to do. It’s worth noting that this is much less likely to happen if you have your boiler serviced regularly as it is something that is checked and, if required, recharged during the service process.

As with all faults and issues on a boiler, ignore it at your peril. Having to top up your pressure all the time is not only a pain, it’s also not resolving the actual fault.

If you are having this issue, give us a call on 0333 5770151 or complete the form on the page and we’d be only too happy to resolve it for you.

Complete the form below and one of the Plumbcare.com team will get back to you as soon as possible.

The engineer was really friendly and polite and cleared everything away